top of page

Product Development

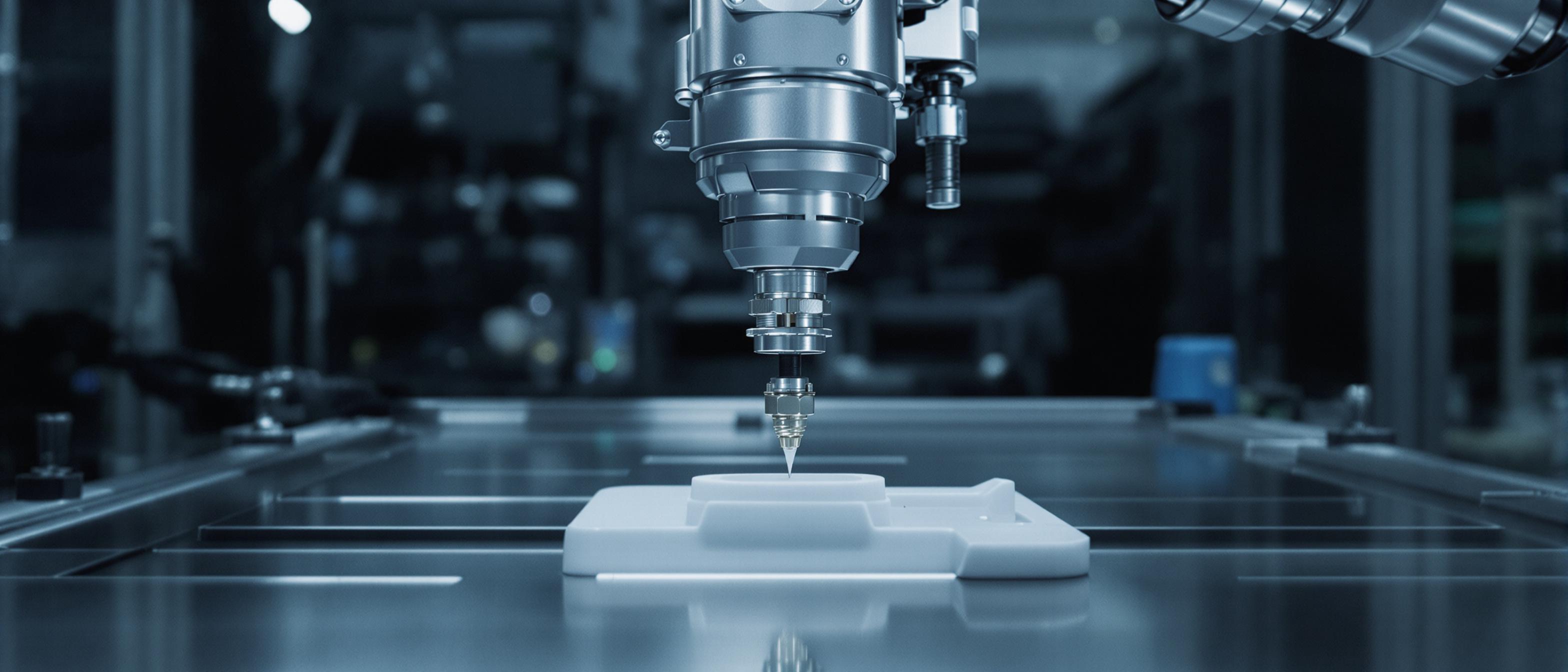

Altera has years of experience assisting customers across multiple industries choose production methods for various types of 3D models. Various software suites and file extensions are utilized. Altera will carefully take file decimation and original file extensions into consideration for part design. Altera will place files into two categories: mechanical and organic.

We have vast experience negotiating organic and complex designs into finished plastic parts.

Product Assessment

Products that endure sometimes can be re-engineered to improve their production cost and OQC targets. Altera can evaluate current designs and production methods in order to determine if alternative methods exist.

Digital Design Implementation

Altera is experienced with extreme tolerances for medical, automotive, and consumer applications.

Altera has many years of experience taking digital files and returning finished parts for prototyping or production. Cantilever, Slide Core, Hand Inserted Core and A/B molds can be created.

Common Tool Base Systems

Altera has implemented common tool bases made of steel to house aluminum or steel tool inserts. By using this logical way of production, companies that produce similar sized products can make mold

production costing simple and efficient.

Injection Molding

Altera has production facilities and partners in China and the USA. Molds are produced in China

and then air shipped in components from Asia to the United States for domestic production. Commonly used resins are Polystyrene, ABS, PEEK, Polypropylene, Nylon and Polyurethane.

Strategic On-Shore

Production

Altera is available for corporations that have been producing overseas and must soon consider solutions for domestic production because of tariffs, political instability or shipping costs.

R&D Capabilities

Cross industry solutions to modern product design is a complex road to navigate. Altera has

experience across several industries and this knowledge can benefit your organization.

bottom of page